Prototype Development

Prototype development is the process of testing your invention to see if it does what it's intended to do - to expose flaws in your concept - or to explore alternative solutions to your design.

It is a "concept testing process" to learn how to reproduce something that will function as you desire, or discover design refinements to reduce production costs. The term "reduction to practice" is the term used to describe this process.

You should record everything you're doing such as test results, experiments, and materials used. Often, multiple versions of prototypes are consecutively constructed and modified to progress to a final design.

Skills and Tools

In prototype development companies, specialized skills and tools are used in this process. You may want to educate yourself about the tools and skills used to fabricate prototypes similar to your invention.

One of these tools is computer aided or animation modeling software that can create virtual, functional, three-dimensional prototypes that can be tested on a computer.

You might also considered consulting or outsourcing certain aspects of your development to an engineer, designer or draftsman.

You might also considered consulting or outsourcing certain aspects of your development to an engineer, designer or draftsman.

You could outsource one part of your prototype to one source and another part to another source. Only you know the purpose of the parts and how they work when combined together.

You should consider consulting with tool-and-die shops, fabricators, technical schools, colleges, universities or trades like welders or pipe fitters. You could also use global outsourcing services.

Outsourcing

Outsourcing has been around for many years but it has steadily increased due to the reduction of global barriers and the evolution of technologies in communication and transportation.

Today, we can have something delivered anywhere in the world the next day and we can communicate worldwide in virtually any medium instantly.

So although global outsourcing may have been difficult or questionable in the past, it is no longer that way. Times have changed. There are now reputable and successful online outsourcing services that facilitate your requirement for an expert to help you with your prototype development.

So although global outsourcing may have been difficult or questionable in the past, it is no longer that way. Times have changed. There are now reputable and successful online outsourcing services that facilitate your requirement for an expert to help you with your prototype development.

The main advantages to outsourcing are: saving money, saving time, and adding value. However, another key advantage is “speed to market” meaning that in a fast paced competitive market you need to move quickly. You can only move quickly if you have the resources to do so and that’s why outsourcing is an advantage.

Outsourcing provides a diversity of qualifications and skill-sets to help deliver those services and products. You can delegate tasks that are repetitive or ongoing, or those you simply don’t like doing. If you need some work done that is expensive in your part of the world, you can have a professional in another part of the world perform equal or better quality work for less money.

A lot of outsourced work is done in developing countries where the economics allow highly skilled individuals to reap better savings and operate within tighter budgets. However, there are also individuals working from their homes looking for part-time income.

This type of work is also scalable, meaning you use it as you need it while reducing costs, increasing productivity and becoming more profitable.

Rapid Prototyping

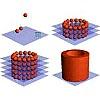

Rapid prototyping uses a 3d printer to make a physical functioning prototype or parts of your invention.

The process is known as additive manufacturing because rapid prototyping can produce a product from computer designs, or modeling software, that look like they've been manufactured.

A digital model is downloaded to a rapid prototype machine or is created on the 3d printer itself.

The 3d printer then forms multiple layers of material (liquid, powder, film) to sculpt your model.

The built-up of layers can create any shape to form your prototype. Various 3d printers create the layers differently. Some materials are melted, others are fused, cured or laminated together.

To utilize rapid prototyping you'll require three-dimensional digital drawings of your invention.

Rapid prototyping is fast compared to other methods of creating a model of your invention. Depending upon the complexity and size of your invention you can create a prototype in a matter of hours or several days.

It's not only fast but less expensive for producing small quantities. You can use a 3d printer for creating parts of your invention for testing a design feature or function.

In this way, you can often identify problematic areas of your design and work to solve it before building a full model of your invention.

Similar to ink printers, the cost of 3d printers has steadily declined and the technology has become so advanced that it's being used in practically every industry to create every conceivable product.

Additive Manufacturing

Inventions that require testing for structural durability or air flow such as an airplane, car or bridge can be tested as computer models and then rapid prototypes of parts can be made for further testing.

Inventions that require testing for structural durability or air flow such as an airplane, car or bridge can be tested as computer models and then rapid prototypes of parts can be made for further testing.

For example, a friend of mine invented a new design for an airplane wing. He tested the design on a computer model and then created a rapid prototype of a scaled-down version of the wing.

The downsized part was only about a meter long (3 ft.) but he used it in a small wind tunnel for testing. This allowed him to prove his principle concept for the aerodynamic benefits of his invention.

Graphic Credits: Zcorp, Svilen

|

| 28-year-old gets millions for his 3D printer invention |

|

| New technology creates human veins and organs. |